Internal Auditing for Manufacturing

Internal audits provide your organization with a systematic, objective evaluation of manufacturing processes, ensuring compliance with ISO 9001 and AS9100, and promoting continual improvement across operations

Key Features

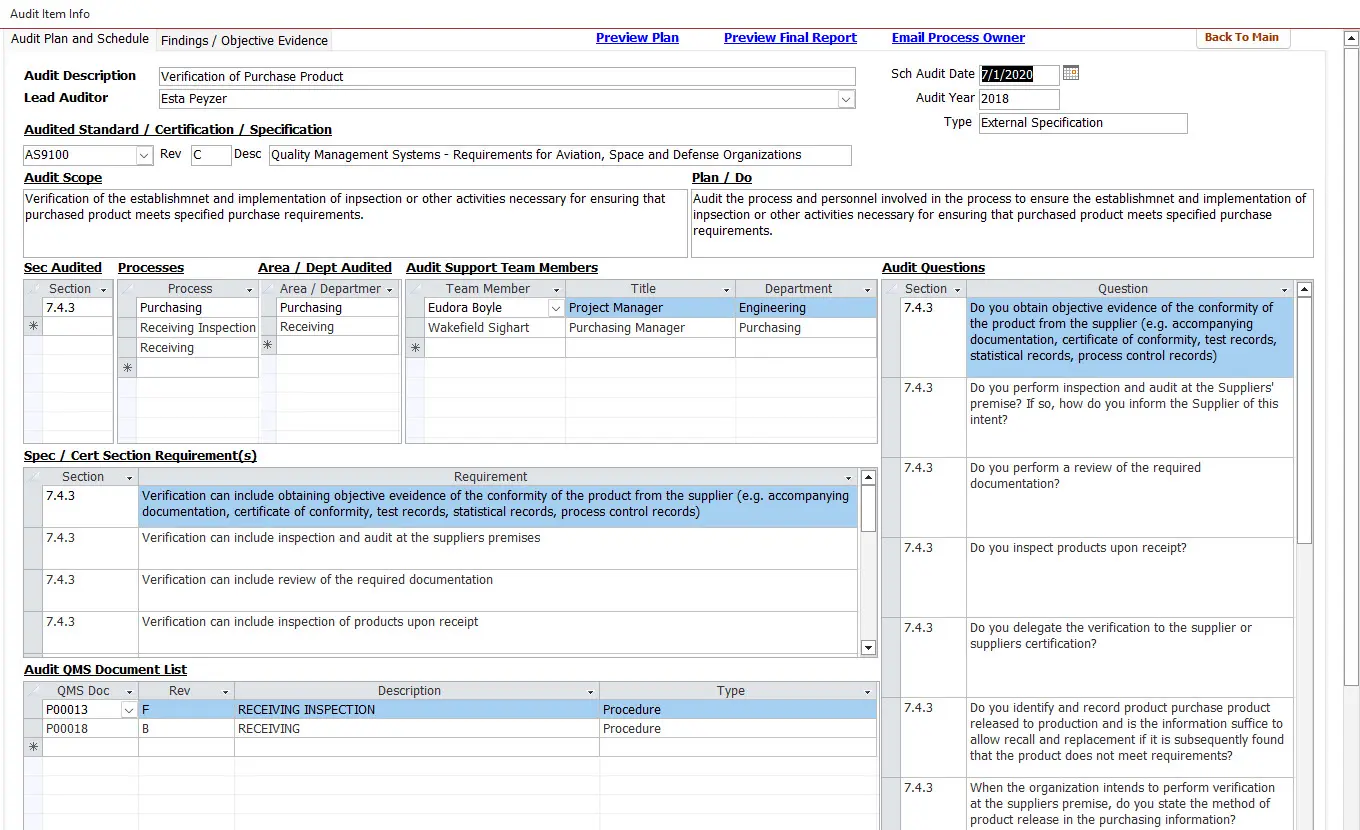

Audit Planning & Scheduling

Set up audit plans, schedule internal audits, and track frequency to ensure all areas are reviewed regularly.

- Create audit calendar by department/function

- Assign auditors and scope

Audit Checklists & Procedures

Use customizable checklists and procedural templates to standardize audits across the manufacturing floor.

- Pre-built templates for ISO/AS standards

- Custom checklists per process or equipment

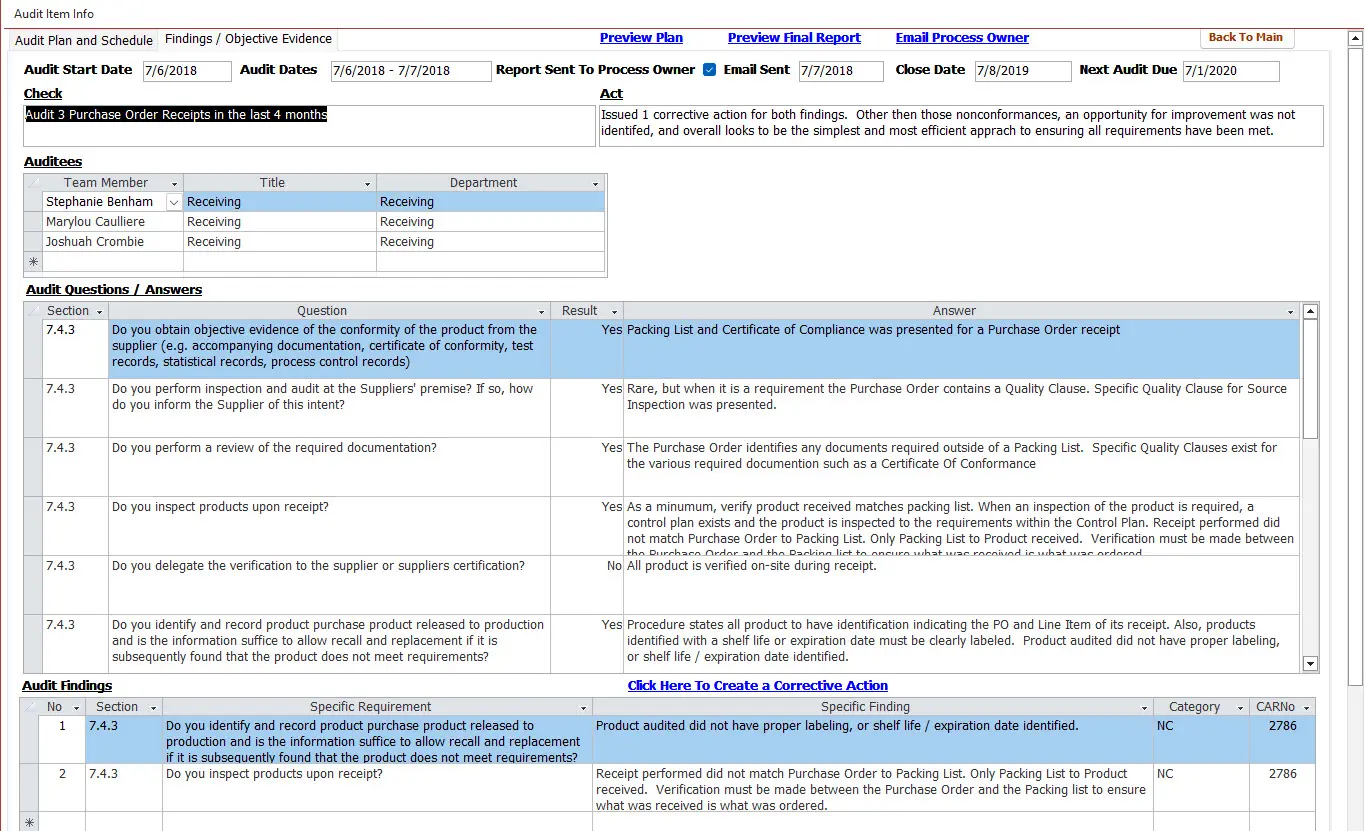

Recording Findings & Evidence

Document audit observations, nonconformance items, and gather evidence (photos, attachments) during the audit.

- Log nonconformities directly

- Attach photos, documents, notes

Link to Corrective Action

Seamlessly integrate audit findings with corrective action workflows to resolve issues and close audit items.

- Generate CAPA from audit findings

- Track audit-to-action linkage

Follow-up & Closure Tracking

Monitor audit findings status, ensure corrective actions are executed, and formally close out the audit items.

- Track due dates, status, verification

- Record closure evidence

Reporting & Trends

Analyze audit outcomes, nonconformance metrics, recurring issues and drive continuous improvement.

- Open audit items, overdue reports

- Trend charts over time

Call for a Free Demo:

858-335-6421