Inventory Management

Managing Inventory drives the maximum amount of profit and customer satisfaction by using the least amount of investment in stock by sharing information within different parts of their business in real-time. Organizations use this data to make more informed ordering decisions and create more accurate forecasts to meet future demand without ending up with excess stock.

Effective inventory management is essential for manufacturing companies for a multitude of reasons:

Cost Control

By managing inventory effectively, businesses can significantly reduce holding costs associated with warehousing, insurance, and spoilage. Additionally, it minimizes the risks of overstocking or running out of stock, both of which can incur hefty expenses.

Efficiency in Production

Having the appropriate materials in the right quantities at the right time is vital for seamless production operations. Inadequate inventory management can result in production delays or halts, jeopardizing deadlines and overall productivity.

Cash Flow Optimization

Excessive purchasing of raw materials can tie up cash that could be better utilized elsewhere in the organization. Conversely, insufficient purchasing can lead to production delays, impacting sales. Striking the right balance in inventory ensures that cash flow remains healthy and not unnecessarily constrained by inventory.

Customer Satisfaction

It is crucial to have finished goods readily available when customers need them to maintain high levels of customer satisfaction. Inventory-related delays can result in lost sales or customer dissatisfaction, which can negatively affect the company’s reputation.

Supply Chain Coordination

Inventory is a key component of a broader supply chain. Effective inventory management guarantees that raw materials are accessible to suppliers, facilitating a steady flow of production materials and preventing bottlenecks or disruptions.

Demand Forecasting

By scrutinizing inventory data, companies can enhance their ability to predict demand and adjust production schedules accordingly, leading to more precise ordering and reduced waste.

Lean Manufacturing Practices

Strong inventory management aligns with lean principles by minimizing waste, such as surplus inventory or unnecessary material movement. This enables companies to boost efficiency and cut unnecessary costs.

Compliance and Traceability

In certain industries, maintaining precise inventory records is vital for regulatory compliance. In instances of recalls or quality concerns, a well-organized inventory system can swiftly trace affected batches.

Overall, effective inventory management empowers manufacturers to operate more efficiently, reduce costs, enhance customer satisfaction, and remain competitive in a rapidly evolving market.

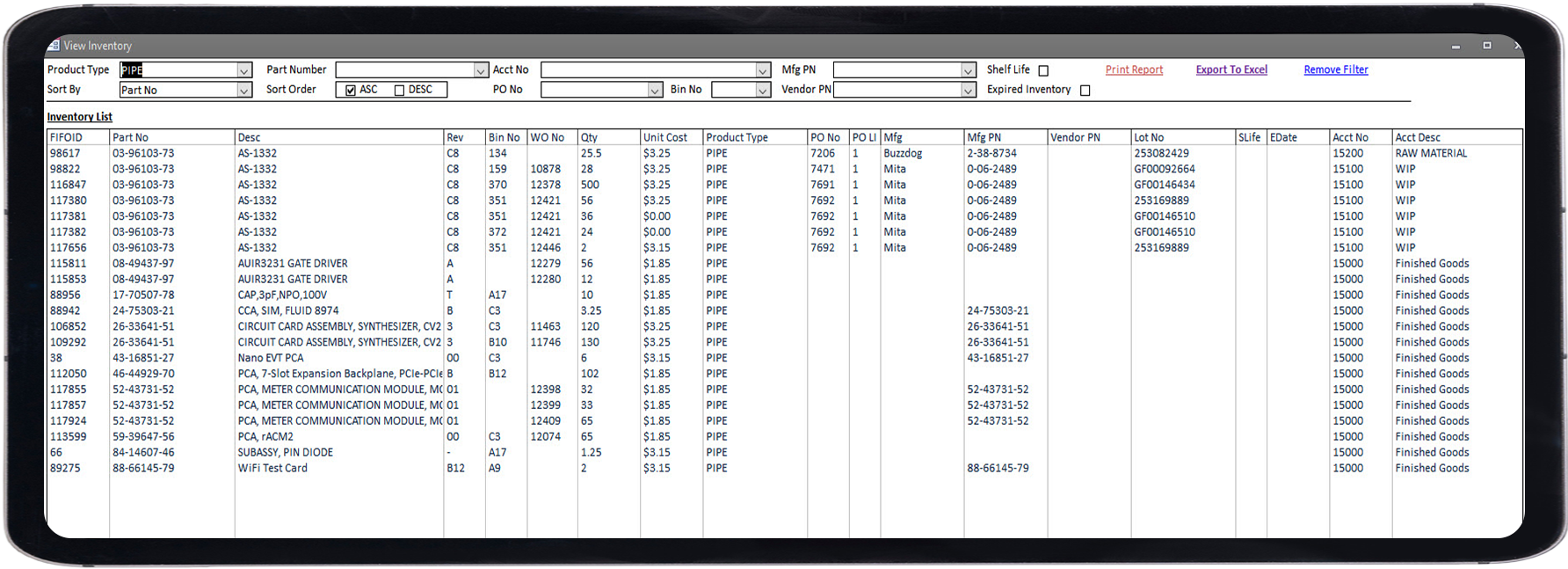

That is why Inventory Management Module is included in SimpleManufacturing™!

Simple Manufacturing

Our Inventory Management Features

Multiple Inventory Locations

First In, First Out (FIFO)

Actual Costing Method

Automated Material Transfers

Complete Transaction History

Manual Material Adjustments, Transfers

Unique Identification

Cycle Counting