Quoting Software for Manufacturing Business

Your Trusted Experts in Quoting Requirements of Manufacturing and Service Businesses

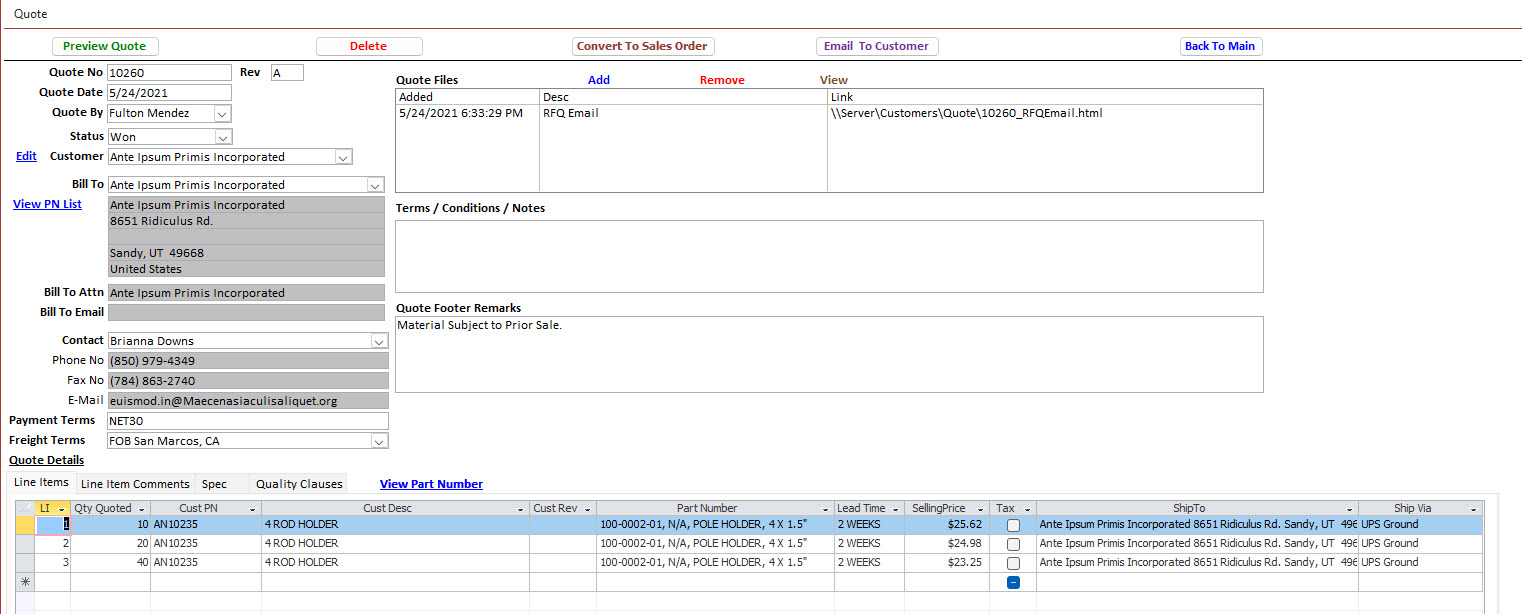

Quoting of Simple and Complex Products is a Breeze using the SimpleManufacturingTM Quoting Module.

Built with Flexibility, Ease of Use, and Efficiency in mind.

Prepare, Track and Manage all Quotes or Request for Quote (RFQ) with this Feature-Rich Module.

Quote Details Unique to Manufacturing and Service Businesses

- Part Number, Revision Level and Description

- Quantity and Delivery Schedule

- Product Specifications

- Tooling and Fixture

- Material, Outside Processing and Labor Cost Estimates

- Overhead Costs

- Shipping and Packaging Costs

- Testing and Quality Control Requirements

- Compliance and Certification Requirements

- Payment Terms

- Risk Factors and Contingencies

Our Quote Management Software Features

Comprehensive Quote Details

Customer Information - Location, Bill To and Ship To Options

Part Number, Revision Level, Description

Quantities and Delivery Schedule

Lead Times

Standards and Specification Requirements

Tooling / Fixtures

NRE and Overhead Costs

Material, Labor, Outside Processing Costs

Link Documents / Files to Quote

Drawings

Emails

Customers Request For Quote

Terms and Conditions

Material Quotes

Labor Estimates

Standards and Specifications

Quality Clauses

Identify All Part Quality Clause

Identify Quality Clauses Per Line Item

BOMs or Bill of Materials

Create Multi-Level BOMs for Easy Transfer When Order Received

Identify Alternate Material

IInclude Tooling / Fixture

Process Flows / Router / Build Instructions

Create Routers for Easy Transfer When Order Received

Identify Equipment / Tooling

Include Inspection Points

Include Outside Processing Steps

Robust Reporting

Quotes Won / Lost

Outstanding Quotes

Include Inspection Points

Quote History

Automation

Single Click Email generation

Electronic Review and Approval Process

Digital Signatures

Importing Supplier Quotes

Import Supplier Material and Outside Processing Quotes

Generates Best Pricing / Lead Time Options

Comprehensive Searching Options

Customers

Quote Date Range

Part Number

Request for Quote (RFQ) Number

Standards or Specifications

Won / Lost