Manufacturing Item Data Management Software

Maintain Product Data Management for Manufacturing With Ease

Accurate and centralized item master data management is critical for optimizing production processes, inventory control, and procurement efficiency.

A well-maintained item master data system ensures that every part, component, and material is consistently defined across departments—from engineering and sourcing to production and logistics.

Key Benefits to Parts Management

By implementing SimpleManufacturingTM robust item master software or part management software:

- Manufacturers Eliminate Duplicate Records

- Pivital Role In Inventory Management - Tracking Inventory Levels

- Enhance Data Accuracy

- Maintain BOM (Bill of Materials) Integrity

- Facilitate more accurate Forecasting

- Streamline Operations

- Enhance Supply Chain Agility - Consistency in Purchase Orders

- Cost Control - Comprehensive Cost Information for Each Item

Our Item Master Data Management Software Features

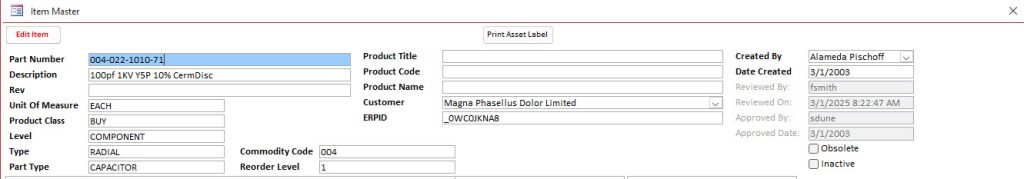

Common Item Data Information

- Part Number, Revision Level, Description

- Product Classification - Buy, Make, Phantom

- Level - Component, Sub-Assembly, Assembly

- Type - Surface-Mount, SRAM, Aluminum

- Part Type - Capacitor, IC, Metal Tubing

- Commodity Codes

- Reorder Level

- Option for Review and Approval of Each Item Record Created

- Product Title, Code, and Name for Branding, Marketing Purposes

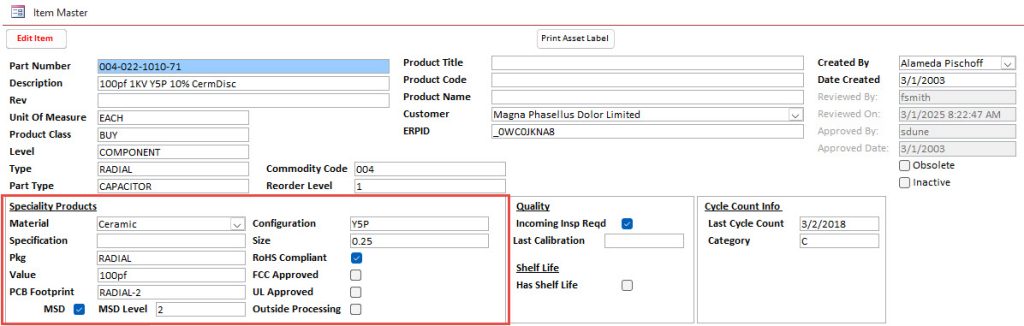

Specialty Product Fields

- Material Type

- Specification or Standard

- Package Layout Name - SolidWorks, PCad, AutoCad

- Value

- PCB Footprint Name - SolidWorks, PCad, AutoCad

- Configuration

- Size

- RoHS, FCC, UL and Outside Processing Attributes

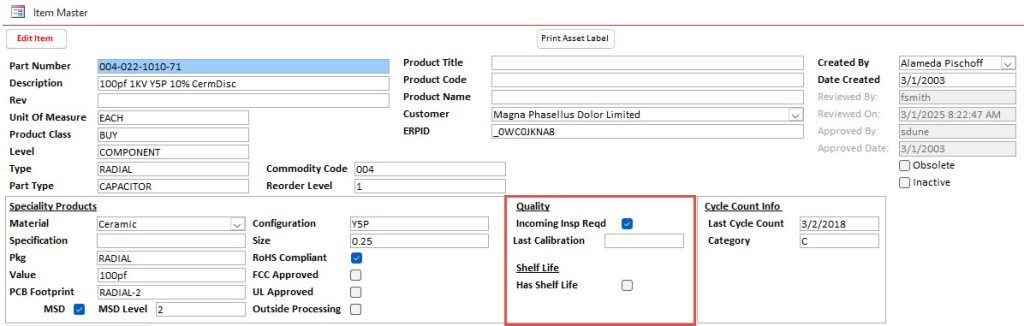

Quality Control Attributes

- Requires Incoming Inspection

- Last Calibration Date

- Part Has Shelf Life

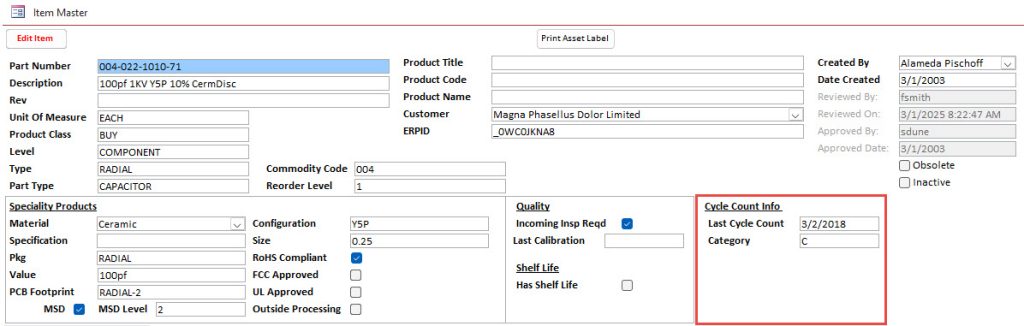

Item Cycle Count Classification

- Last Cycle Counted

- Cycle Count Part Classification

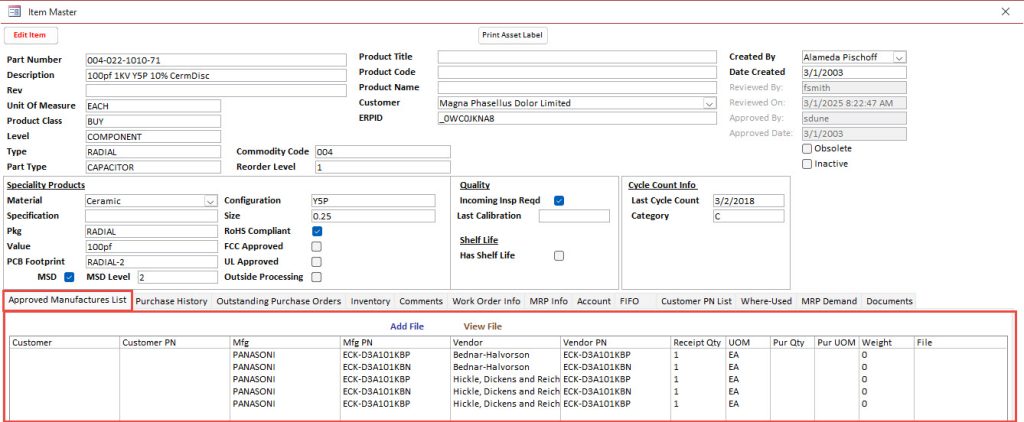

Approved Manufacturer and Vendor List (AML / AVL)

- Option To Identify the Manufacturer and the Manufacturer Part Number

- Option To Identify Vendor and Vendor Part Number

- Option To Identify Customer and Customer Part Number

- Option To Identify the Receipt Quantity and the Purchase Quantity

- Option To Identify Unit Weight

- Option To Link to Datasheet, Vendor's Product Webpage

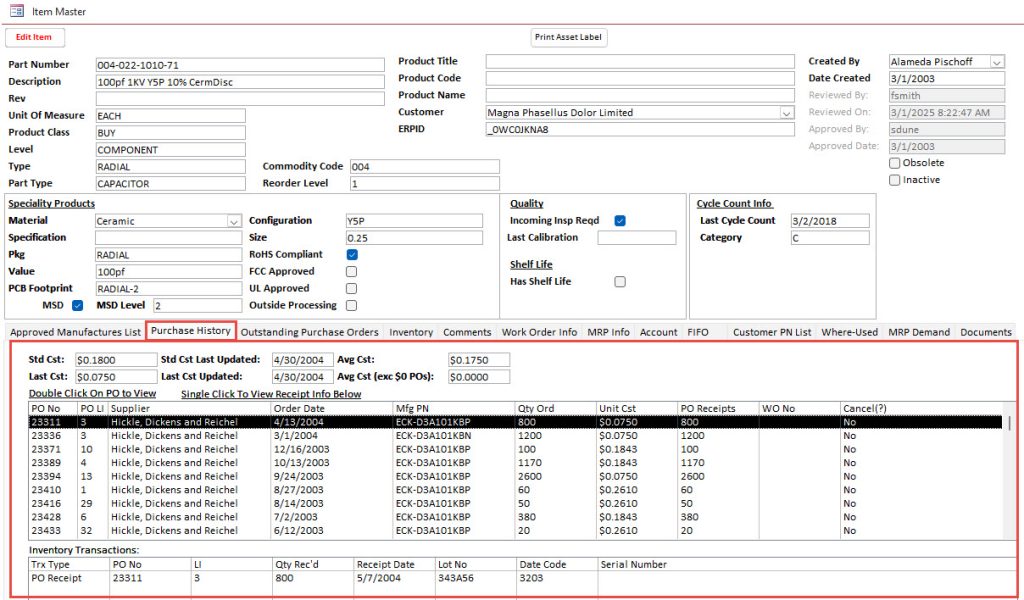

Real-Time Purchase History Information

- View All PO History - Suppliers, Quantities, Unit Price, Mfg PN

- Click to View All PO Receipt Transactions for Specific PO Line Item

- Single-Click to View Purchase Order

- View Last Standard and Average Cost

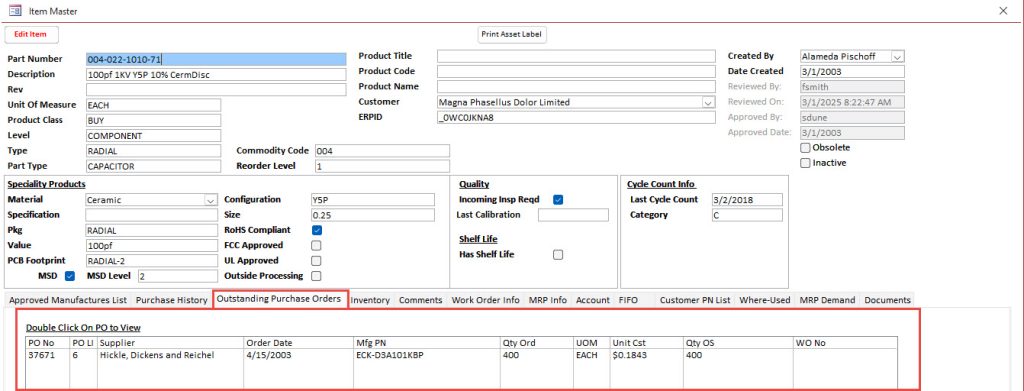

Real-Time Open Purchase Orders

- View Open Purchases Orders - Quantities, Unit Price, Due Date, Mfg PN

- Click to View Purchase Order

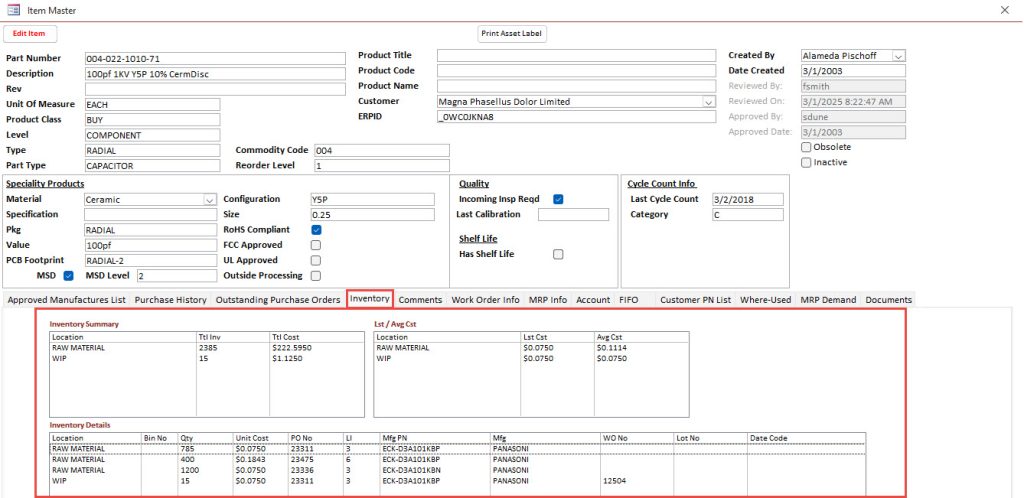

Real-Time Inventory Levels

- View Total Quantity by Inventory Locations - Raw Material, WIP, Finished Goods

- View Last Cost and Average Cost By Inventory Locations

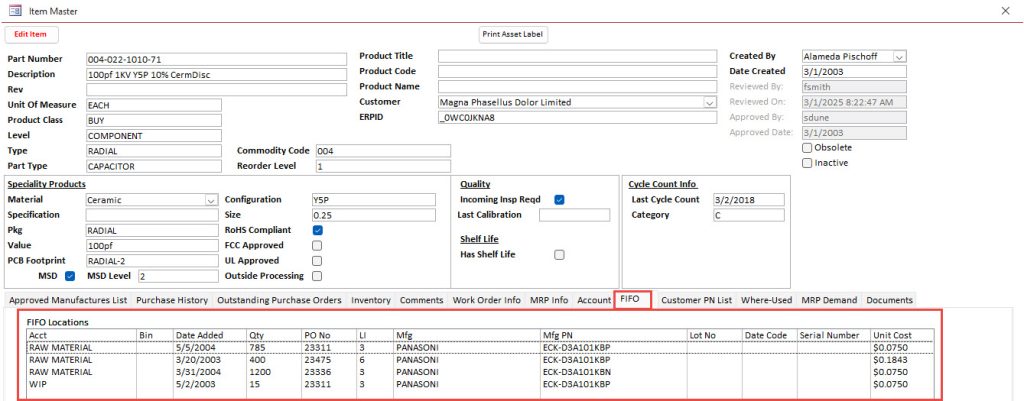

- View First-In, First-Out (FIFO) Details of Each Inventory Location

- FIFO Inventory Is Actual Cost

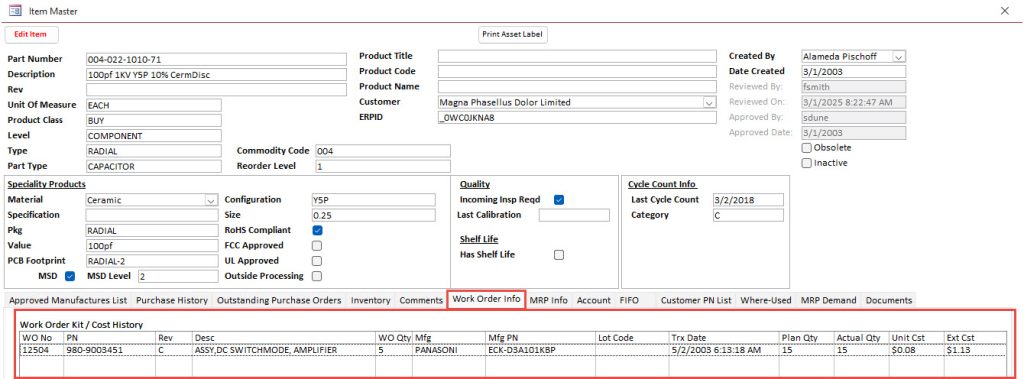

Work Order History

- View All Work Orders Item Has Been Issued To

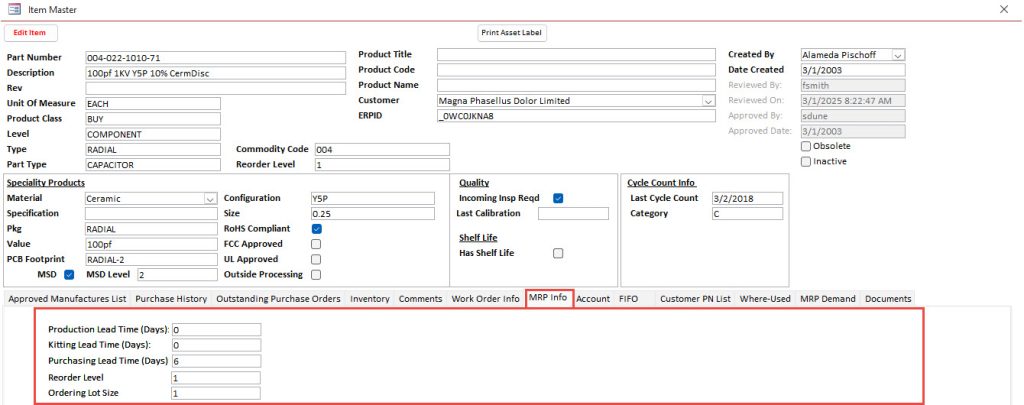

Material Requirements Planning (MRP) Item Definition

- Define Production Lead Time (Days)

- Define Kitting Lead Time (Days)

- Define Purchasing Lead Time (Days)

- Identify Reorder Level

- Identify the Ordering Lot Size

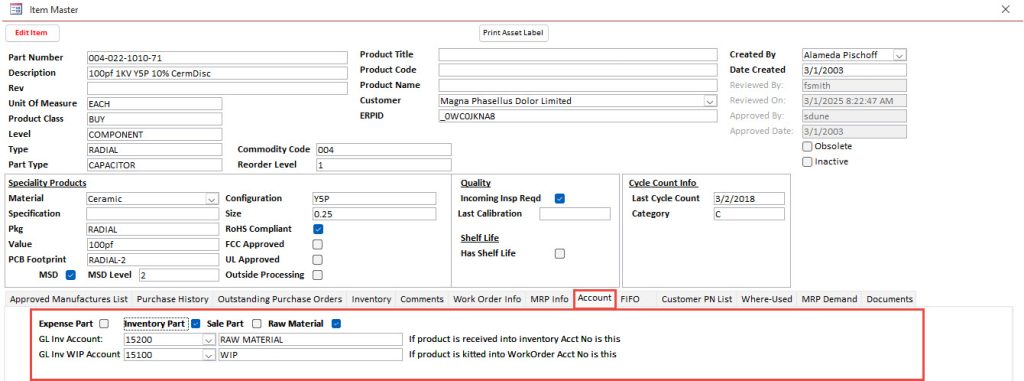

Accounting Defaults

- Identify Item Expense or Inventory

- Identify Item Sale Part

- Identify Item Raw Material

- PO Receipt, Kitting, Work Order Completion, Shipment

- Identify All Default Chart of Accounts for All Automated Transactions

Real-Time First In, First Out (FIFO) Inventory Details

- View All FIFO Inventory

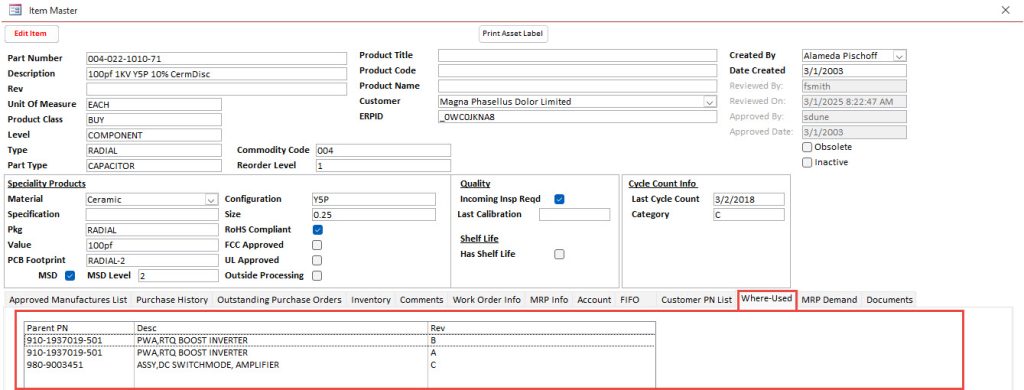

Real-Time Where-Used Information (BOMs)

- View All BOMs (Bill of Materials) Item Is Included

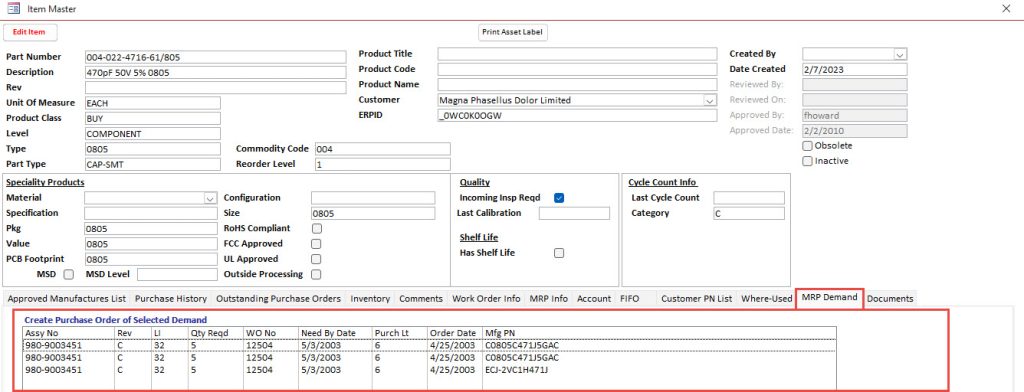

Material Requirements Demand (MRP)

- View All Demand for this Item

- Single-Click to Create Purchase Order

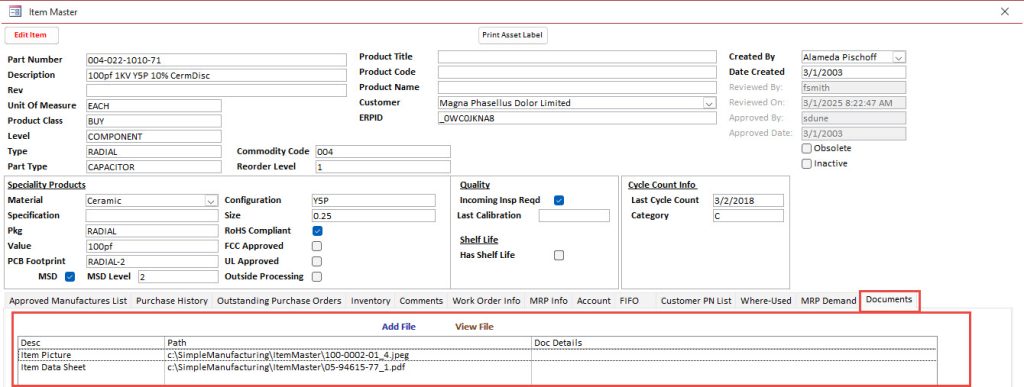

Document / File / Website Link

- Link Unlimited Documents / Files / Website Pages to Item

- Single-Click to Open or View any Linked Item

Ready for an Effective Solution For Item Master Management?

Reach out to us today to discuss how our Part Management Software can transform your organization’s items and parts from chaos into an Accurate and Centralized source of part information.

.

From free demonstrations to customization discussions, we’re here to help you take your manufacturing business to the next level.