Advantages & Disadvantages of an Intelligent Part Number Scheme in Manufacturing

Intelligent part numbers (IPNs) are structured codes that embed meaningful attributes into a part number. They can improve search, traceability, and decision-making — but they also create constraints. This article walks through both sides and offers practical guidance for choosing the right approach for your shop floor and ERP.

Quick Outline

What is an Intelligent Part Number? — A structured identifier where segments encode attributes like type, material, revision, and customer. Contrasts with dumb (numeric) part numbers which carry no meaning.

Why it matters — Affects how teams search, report, and integrate with ERP, PLM, and quality systems.

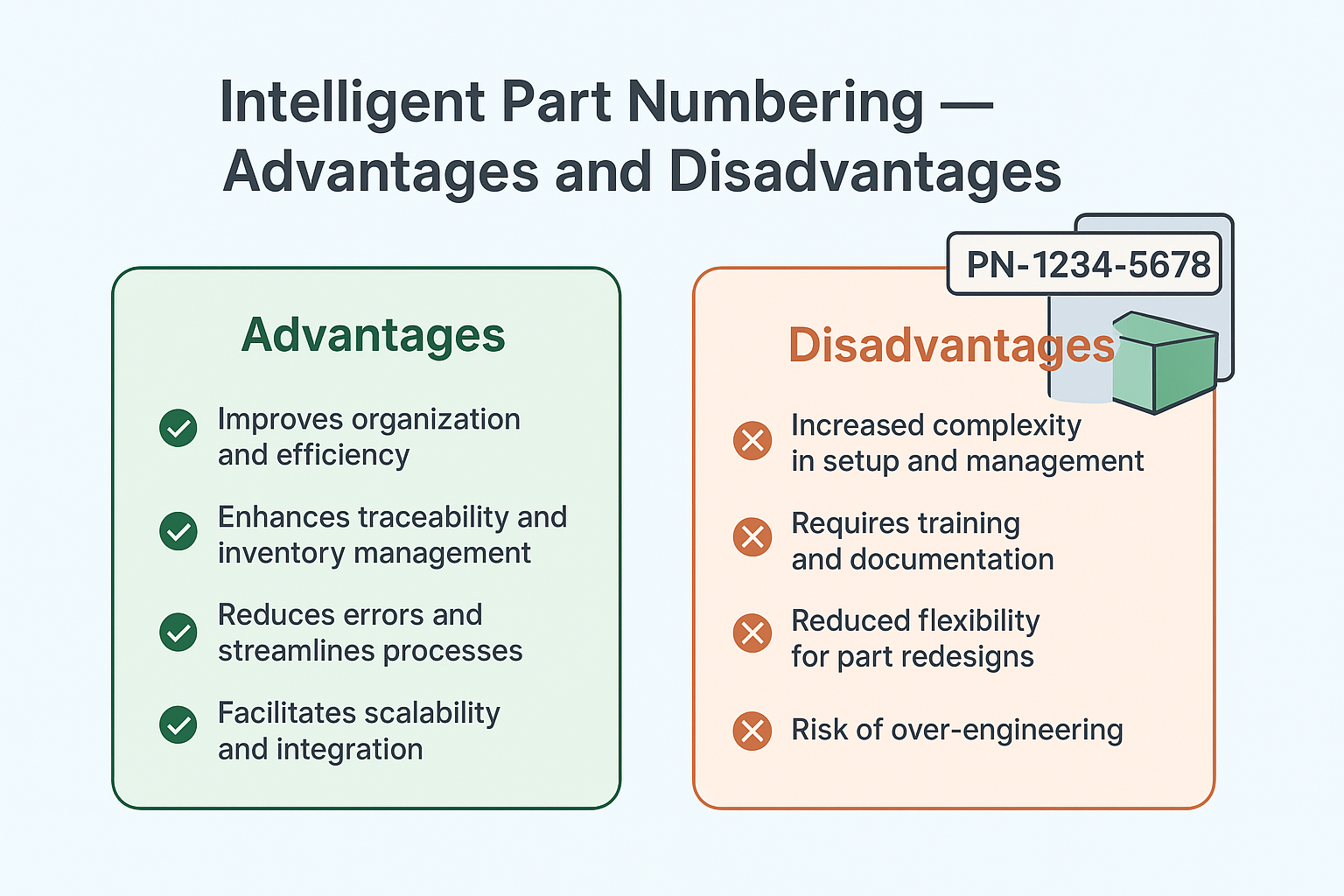

Advantages — faster search, human-readable context, better sorting and grouping, improved traceability in some cases.

Disadvantages — rigidity, risk of misinterpretation, maintenance overhead, challenges with evolving products.

Best practices — hybrid approaches, governance, mapping tables in ERP, training, and migration planning.

What Makes a Part Number "Intelligent"?

An intelligent part number embeds semantic meaning into its segments. Example: BRG-6203-SS-A1 could mean: bearing (BRG), size 6203, stainless steel, revision A1. Each segment communicates something useful without opening a drawing or BOM.

Advantages (What You Gain)

- Faster human comprehension

Operators and buyers can quickly infer basic attributes, reducing lookup time. - Improved searching and filtering

Teams can use logical segments to filter parts (e.g., show all SS parts using the SS token). - Better sorting and grouping

Reports can group by encoded attributes without extra database fields when legacy systems are limited. - On-the-floor clarity

Shop-floor labels that include meaningful codes reduce errors when people read part numbers during assembly or inspection. - Lightweight traceability

For some companies, an IPN gives quick clues during audits and corrective actions by surfacing material, revision, or customer codes in the identifier. - Standardization nudges

Designing an IPN often forces business stakeholders to agree on categories, units, and materials — a governance benefit in disguise.

Disadvantages (What Can Go Wrong)

- Rigidity

Once a scheme is in use, changing it is painful. As products evolve, the scheme can become a constraint rather than an aid. The intelligence becomes broken. - Ambiguity and human error

Different users will parse tokens differently unless strict rules are enforced. A misplaced dash or inconsistent token length creates chaos. - Length and readability

Long, information-dense codes can become unwieldy on labels and difficult to verbally communicate. - Data duplication

When meaning is in the code, teams sometimes duplicate the same data in BOMs and ERP fields — creating reconciliation headaches. - Internationalization & localization

Country codes, units, and language-specific tokens can make a scheme less portable across regions. - Tooling mismatch

Modern ERPs and PLMs prefer attribute-driven models. An IPN attempts to store attributes in a string rather than in structured fields, which can undermine data integrity when systems integrate.

Common Pain Points

Manufacturers who adopt an IPN but lack governance see intelligence drift (different meanings assigned to the same token), collisions (two parts end up with the same code), and long migration projects when reversal is required. These pain points often trace back to missing ownership and poor change control.

Hybrid Approach: The Best of Both Worlds

Many modern shops choose a hybrid model: keep a short, stable numeric core (a dumb identifier) stored as the canonical key in ERP, and expose a human-friendly, semi-intelligent code for labels and shop use. Map both to structured attribute fields in the database. That way, integrations rely on the stable numeric key while people retain the readability they like.

Best practices for designing an IPN

- Keep it short

Minimize tokens and avoid long free-text fields in the code. - Define the "Intelligence" clearly

Publish a "Scheme" dictionary and make it part of your controlled documents. - Limit encoded attributes

Only encode attributes that are unlikely to change and are broadly useful (e.g., material family, major family/class, controlled revision). - Use separators consistently

Dashes, underscores, or fixed-width segments — choose one and enforce it in tooling. - Plan for change

Add a reserved segment for legacy or custom flags and never encode vendor-specific transient data. - Governance & Owner

Assign a part-number "owner" who approves new scheme variationa and enforces rules. - Field-mapping in ERP

Mirror each encoded token into a structured field in the ERP so that reports and integrations don't need to parse strings.

Migration tips

If you already have an IPN and want to modernize, follow a staged plan:

- Audit your current scheme/li>

- Identify collisions, create a mapping table (old code → canonical ID → structured attributes)

- Pilot with one product family before a full roll-out.

Keep both identifiers in parallel during the transition and update labels and BOMs incrementally.

When an IPN is the right choice

Use an intelligent scheme when your team needs rapid human readability and when your shop has limited digital tools. For small-to-mid sized manufacturers with fewer SKUs and a stable product set, an IPN can improve efficiency quickly and cheaply.

When to Avoid It

If your company expects fast product variation, heavy configurability, global expansion, or deep ERP/PLM tool usage, avoid encoding attributes into the part number. Instead, optimize structured attributes and use search, filters, and dashboards to give users the same benefits without the downsides.

Summary

An intelligent part number can be a practical tool when used sparingly and governed well. It provides human readability and quick grouping but risks rigidity, misinterpretation, and future migration costs. Prefer hybrid models and mirror encoded tokens into structured ERP fields to get the benefits while protecting data integrity.

Start Streamlining Your Manufacturing Process — Get Started Now