Bill of Materials (BOM) Management

Efficiently create, manage, and control accurate Bills of Materials (BOMs) with SimpleManufacturing™ ERP. Reduce errors, optimize costs, and streamline production planning while ensuring high-quality standards.

Why BOM Management is Essential

- Accuracy and Efficiency: Reduce errors and ensure smooth manufacturing by accounting for all components.

- Cost Management: Track each component’s cost to improve budgeting and financial planning.

- Inventory Control: Maintain optimal inventory levels, preventing shortages or overstocking. See

Inventory Management Module. - Production Planning: Use BOMs as a roadmap for scheduling and resource allocation. Learn more in our

Production Planning Module. - Quality Control: Ensure correct components are used for consistent product quality.

- Traceability: Easily trace component origin for compliance and quality assurance.

- Collaboration: Serve as a central reference for engineering, manufacturing, and procurement teams.

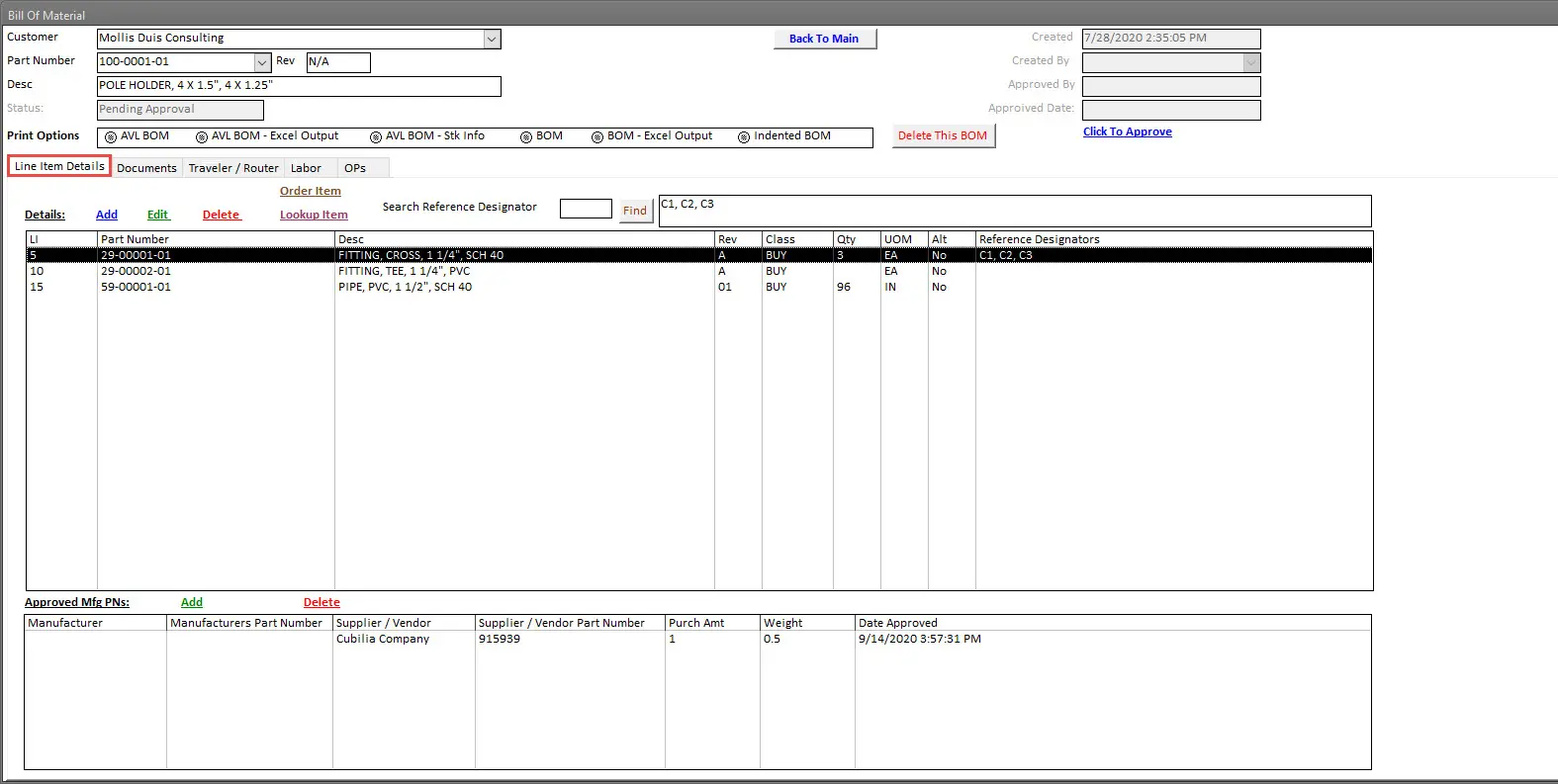

Key Elements of a BOM in SimpleManufacturing™

- Bill Of Material Level (Hierarchy of items)

- Part Number (Unique identifier)

- Part Name (Descriptive name)

- Quantity required for assembly

- Unit of Measure

- Description and specifications

- Procurement Type (Make, Buy, Phantom)

- Lead Time

- Cost per item

- Supplier Information

- Revision Level

- Assembly Instructions

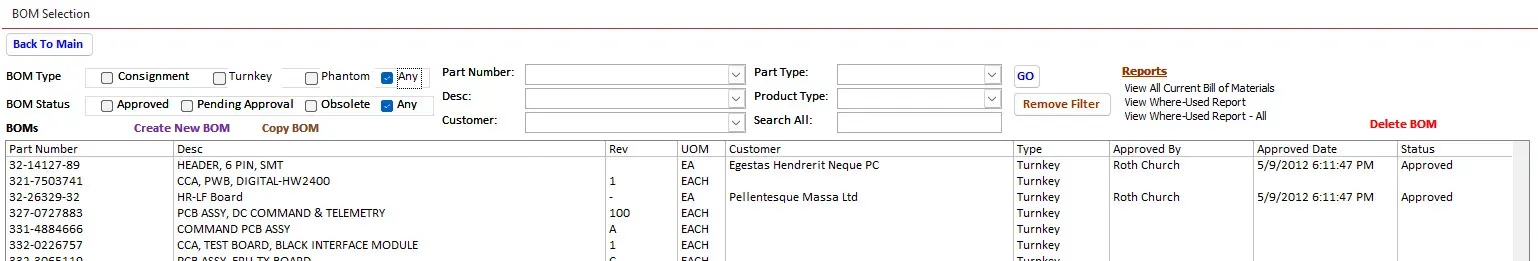

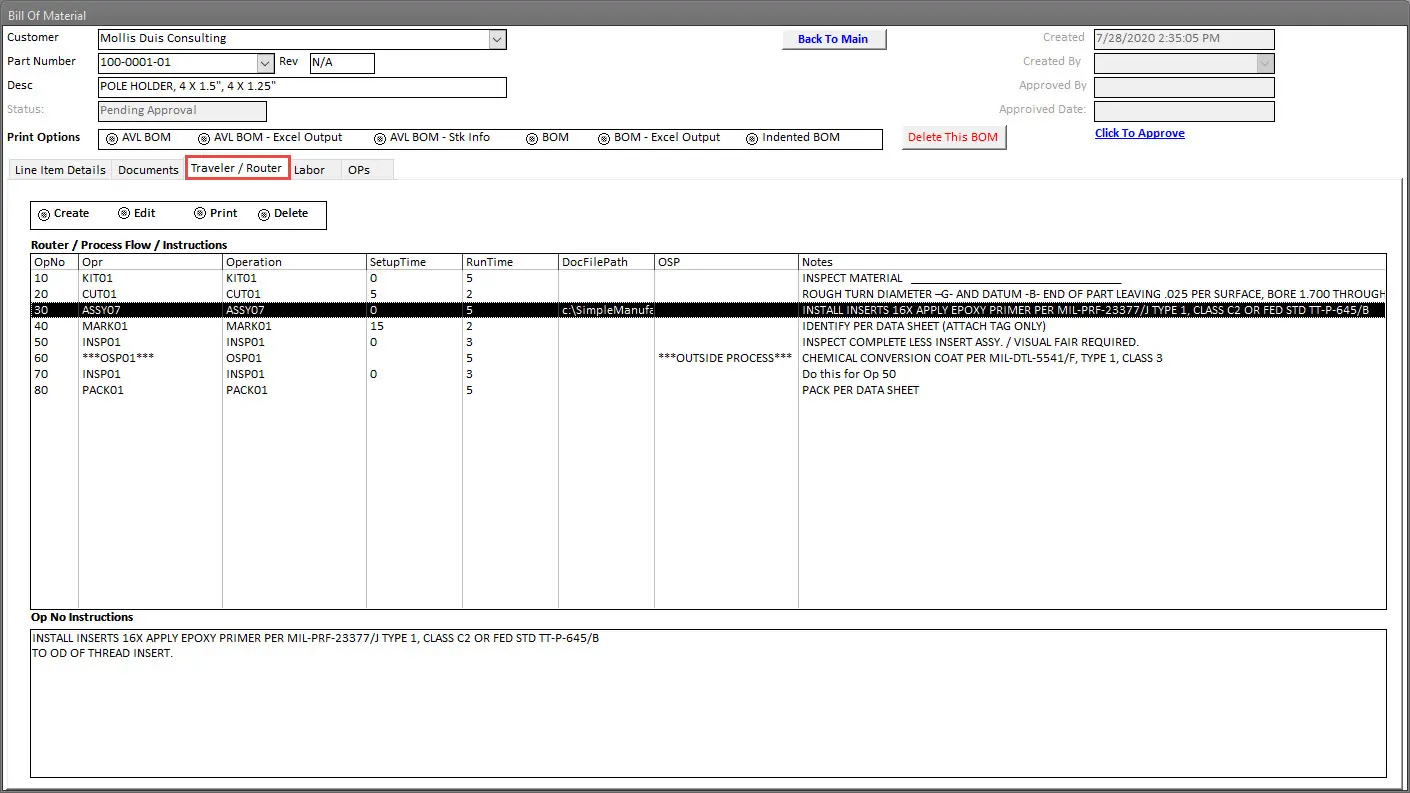

Advanced BOM Features in SimpleManufacturing™

- Primary / Alternate Parts

- Approved Vendor / Manufacturer Part Numbers

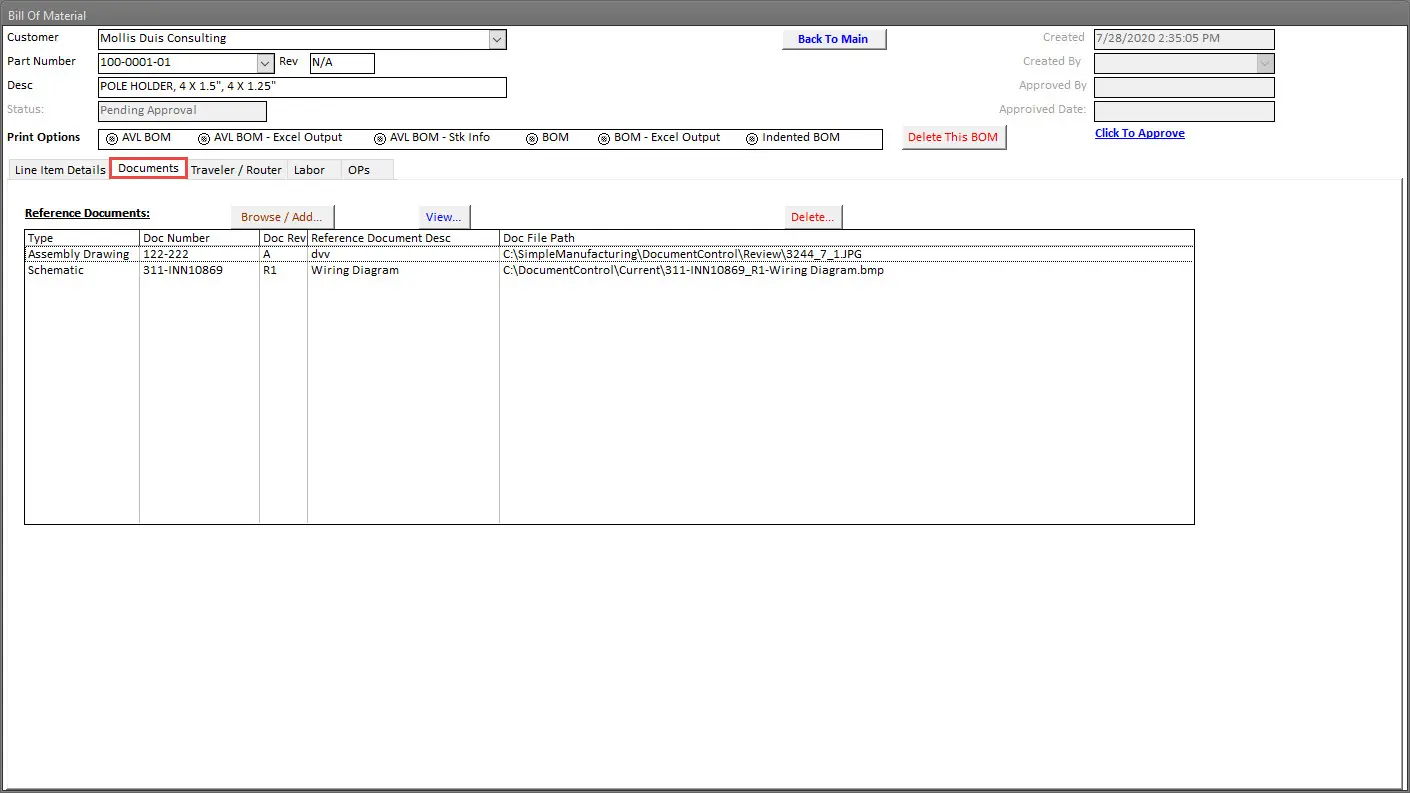

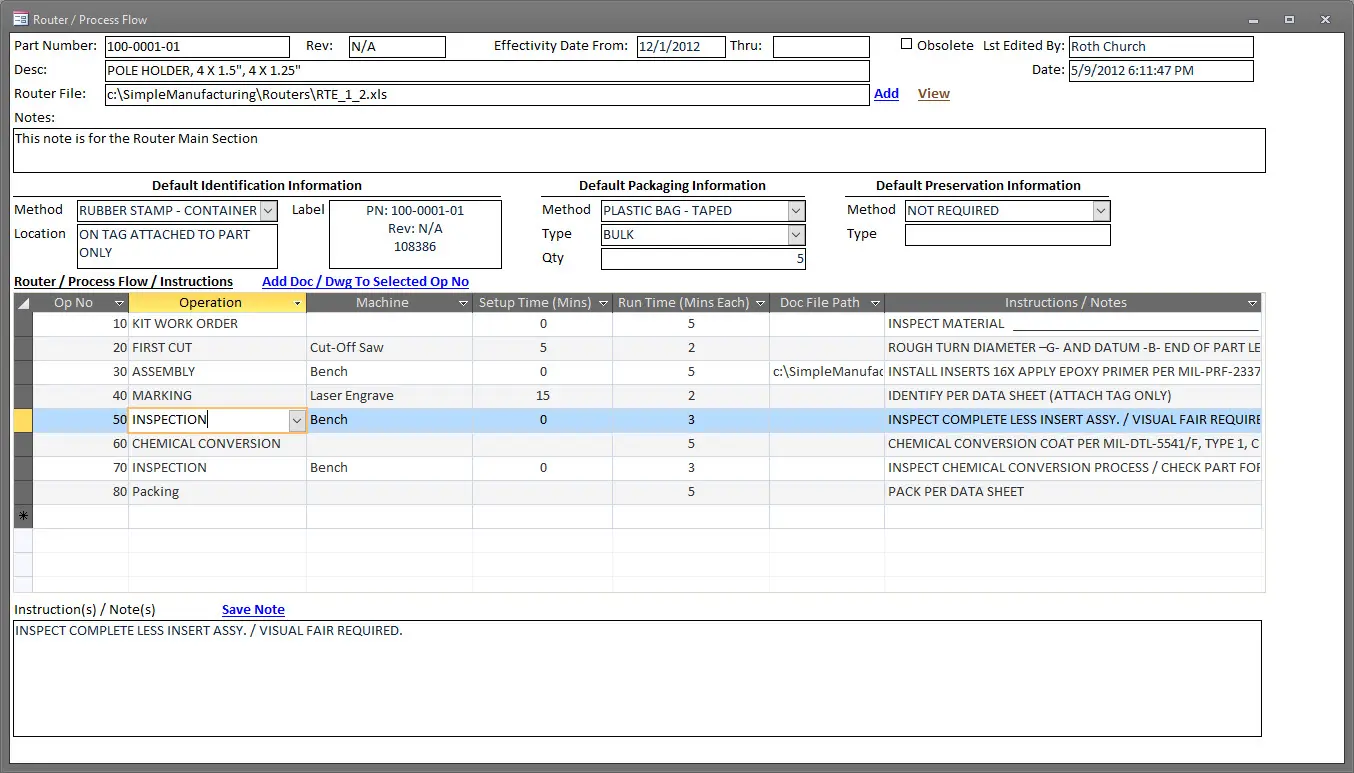

- Document Links (CAD, Assembly Drawings, Work Instructions, Gerbers, X-Y Data)

- Router / Traveler / Process Workflows

- Reference / Drawing Locations

- Review / Approval Options

- Reports (Indented BOM, AVL, Inventory Availability, Excel Export)

- Comprehensive Search (by part number, vendor, revision)

- Data Change History

- Labor / Outside Processing Standards

Downloadable BOM Template

Get started quickly with our free, ready-to-use BOM Template. Customize it to your manufacturing process and ensure accurate BOM tracking from day one.

Download Free BOM Template

Ready to manage your Bill of Materials efficiently? Discover how SimpleManufacturing™ can streamline your manufacturing process.

Request a Free DemoCall Now: 858-335-6421

Learn More About Our ERP Modules

Inventory Management Item and Part Number Management Manufacturing Planning Full ERP Software Overview