What is an Item Master?

An item master is a list of unique item numbers for all the material purchased, items included within a product, or items used within the manufacturing of an item such as equipment. Furthermore, how it is used, what it will contain and who manages the list are all questions that vary from business to business. An item master may include things like:

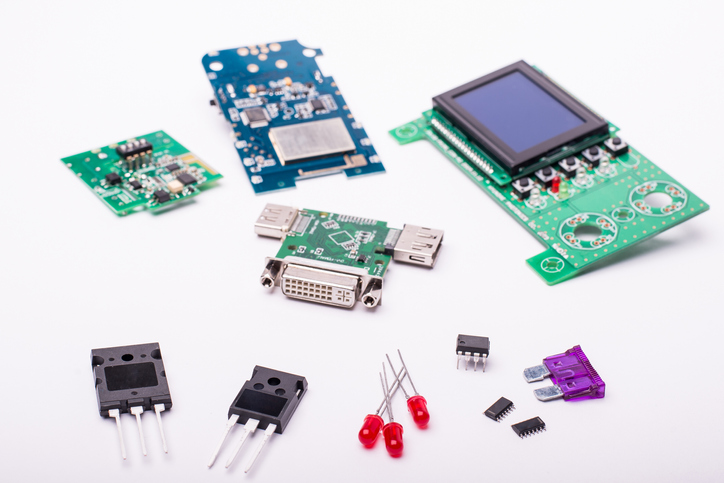

- Tangible items (parts) used in your products such as electronic components, raw materials, such as metals and textiles, to items that could be used during manufacturing such as fluids, glue, mills, drills bits, etc.

- Non-tangible items such as Gerber’s, CAD Data, NRE costs, labor costs, and Quality Management System procedures, forms, work instructions.

- Manufacturing and Test Equipment such as ovens, compressors, CMM Machines, oscilloscopes and other equipment assets for inventory tracking, calibration records, and depreciation.

An item master is a collection of all the important details about a specific item – inventoried or not.

Why is an Item Master Important?

When it comes to item information, this is the one place within any ERP software where supply chain analysts, engineers, sales and operations employees alike can look to find everything about an item from the item’s suppliers, unit inventory, usage, and the rest of the Item’s important attributes.

Additionally, a well-maintained item master data helps businesses stay on top of inventory management, avoid overstocking and shortages, and provide information to facilitate high-level decisions. Item masters require a lot of data — carefully collected and analyzed — but creating them doesn’t have to be difficult. SimpleManufacturing™ makes it Simple!

Why do I Need An Item or Part Master?

An Item is the Single Source of Truth:

The one place for all manufacturing, engineering and ongoing operations to go to for information.

Relevant Information:

Organizations need to decide what information and attributes of an Item are relevant to its business. As expected, Manufacturers have a lot of information about their product. The Item Master can include information pertinent to the Item’s use and definition within the organization.

Simplifies Supply Chain and Reduces Inventory Overhead:

An item master helps facilitate the reuse of common parts. As the number of items increase over time, the item master becomes the primary location for sourcing items for new designs or changes. It is more efficient to identify existing items to use, than searching the various supplier websites for items. In addition, using existing items may use up existing inventory, reducing inventory overhead.

An Item provides Business Intelligence:

When an Item Master is used within SimpleManufacturing™, it provides real-time data on any Item, such as:

- Approved Manufacturer / Vendor / Suppliers and Purchasing Part Numbers

- Outstanding (Open) Purchase Orders

- Purchase Order History

- First-In, First-Out (FIFO) Inventory Levels,

- Actual, Last, Average and Standard Costing

- Work Orders Item Has Been Issued To

- Customer Part Numbers Associated with Item

- Where-Used List

- Material Requirements Planning Demand

- Manufacturing and Purchasing Lead Times

Item Master Facilitates the Everyday Processes:

Having an item master that is accurate and well-maintained results in a single-click solution to submit to suppliers for quotes, or creation of Supplier Purchase Orders. Item demands identified through the Material Requirements Planning function are clearly displayed, so surprise shortages become a thing in the past. In addition, Bill of Materials management becomes straightforward. Likewise, Work Order item kitting process can now be automated, clearly identifying shortages.

Considerations when choosing an ERP Item or Part Master for your business.

It is important that businesses review their goals, objectives and needs from an Item Master perspective. Hence, understanding the What’s and Whys of the Item Master is critical. Many stakeholders, ranging from engineering, manufacturing, sales and quality assurance to suppliers and customers, are essential to help determine which features and definable attributes of an Item are necessities and which are a nice-to-have option.

Item attributes are controlled within the item master data and the attributes are used throughout the different modules within SimpleManufacturing™, and by various functional groups such as supply chain, quality, production, sales, stock room, engineering, etc.

Item data is a critical piece of SimpleManufacturing™. How it is defined impacts various modules. Meanwhile, Careful planning and expertise is required in creating and defining an Item with the appropriate attributes that are useful for all.

Common attributes of an Item are:

- Part Number,

- Description

- and Revision Level are minimal and critical to identifying the Item / Part.

SimpleManufacturing™ Item Master module, accommodates different business types, by providing additional attributes, such as:

Physical Attributes

- Dimensions,

- Material Type,

- Size,

- Value,

- Tolerance

Plethora of Unit of Measures

- Each,

- Kgs,

- Lot,

- Inches, feet, meters, millimeters, etc.

Compliancy Classifications

- ROHS,

- FCC,

- UL, etc.

Type of Item

- Sales Item,

- Purchased Item,

- Make Item

- Phantom Item

Inventory Classification

- Inventory Item,

- Expensed Item

Classification of Item

- Raw Material,

- Assembly,

- Tooling,

- Jig,

- Fixture,

- Programming File,

- Test File,

- 3D Printing File,

- Procedure,

- Policy,

- Form, etc.

Serialization

Financial Classification

- Expense,

- Inventory,

- WIP,

- Finished Goods,

- COGS

Using Customer or Internal Part Number

Supply Chain Classifications

- Minimum Buy,

- Production, Purchasing and Kitting Lead Times,

- Minimum Stock Levels,

- Standard, Actual and Last Costs,

- Approved Suppliers and Supplier Part Numbers

- Production Lead Times,

Unlimited Number of Files can be linked to Item and viewed with a single-click

- Datasheet,

- BOM,

- Drawing,

- Specification

Choosing SimpleManufacturing™ as your next Item Master Solution

Maintaining an effective item master data in SimpleManufacturing™ is Simple! Creating item masters, even in a small product-based business, is indispensable. To get the most value out of the item master data, companies need software that is focused on efficiencies – such as simplifying inventory management processes, automating key analysis, and optimizing purchasing and production planning and execution.

Spreadsheets and ad hoc analysis can only get a business so far. Where as the amount of data increases and the timeliness of the information becomes critical, a system like SimpleManufacturing™, provides the flexibility to grow with the business.