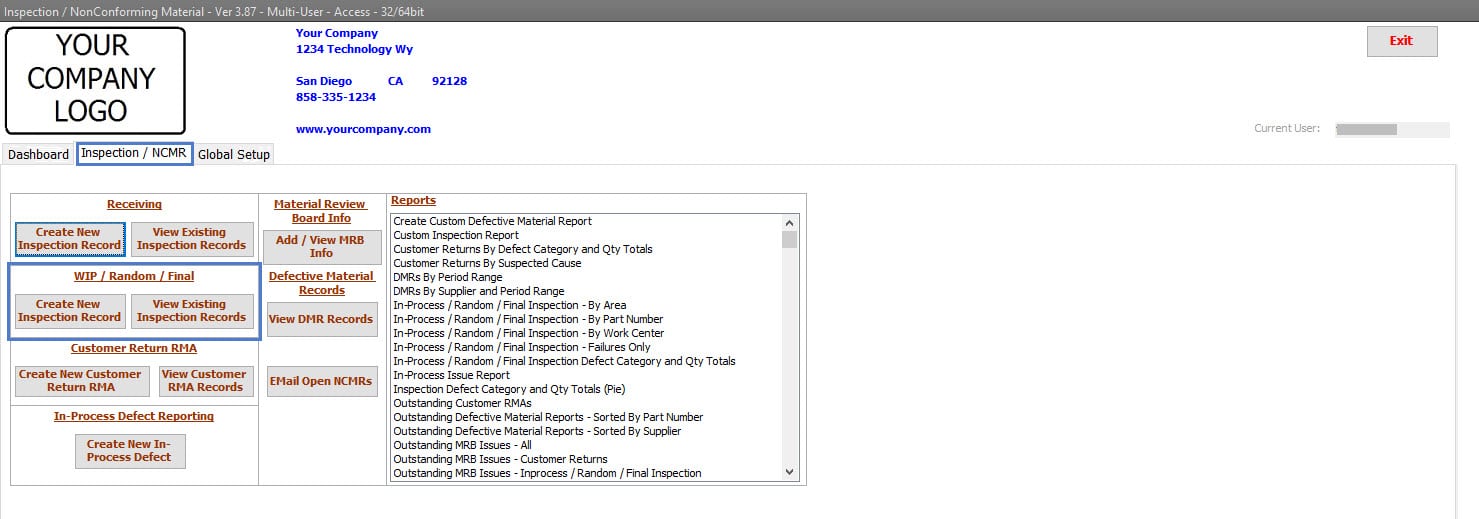

Work-In-Process Inspection / Final Inspection / Audit

Work In Process Inspection

This section can be used to record all Work-In-Process (WIP), Final Inspections and Random Audit Inspections performed, or only those where nonconforming material is identified.

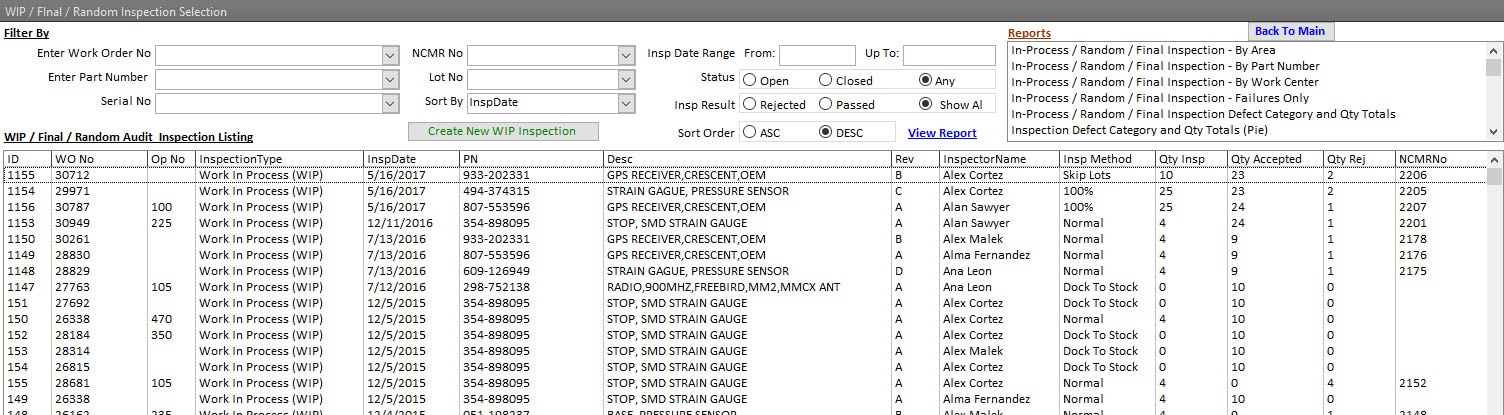

Work In Process (WIP) Inspection Search and View

Work-In-Process (WIP), Final Inspections and Random Audit inspection records can be searched using various fields and any combination of the fields.

All Reports revolving around Work-In-Process (WIP), Final Inspections and Random Audit inspection records can be Viewed with a double-click.

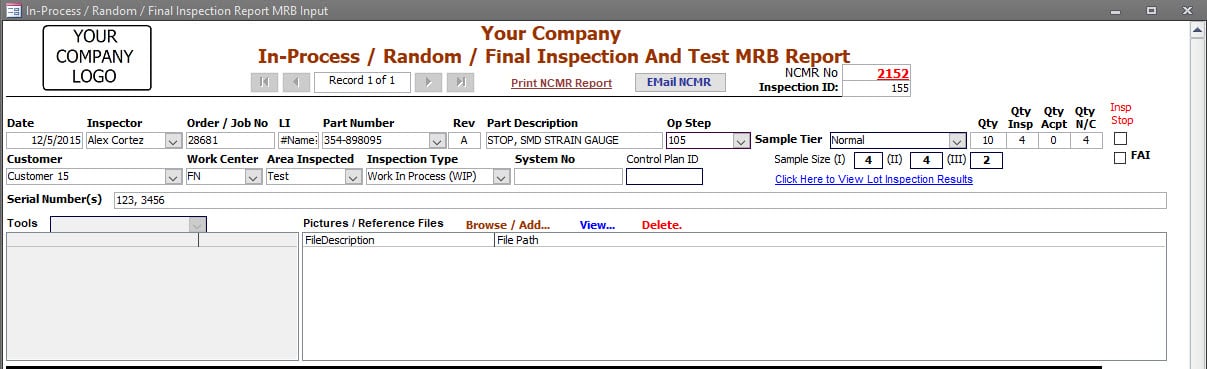

Work In Process (WIP) Inspection Information

For Work-In-Process (WIP) or Final Inspection entry, many common fields are available. The organization should decide what information has value and should to be populated. Common fields that exist are:

Inspection Date,

Part Number, Part Description, Part Revision Level,

Work Order Number,

Lot Quantity, Quantity Inspected, Accepted and Rejected.

Other fields, such as;

System Number,

Customer,

Work Center and Area Inspected,

Serial Numbers,