Receiving Inspection NonConformances

Receiving Inspection – Nonconforming Product

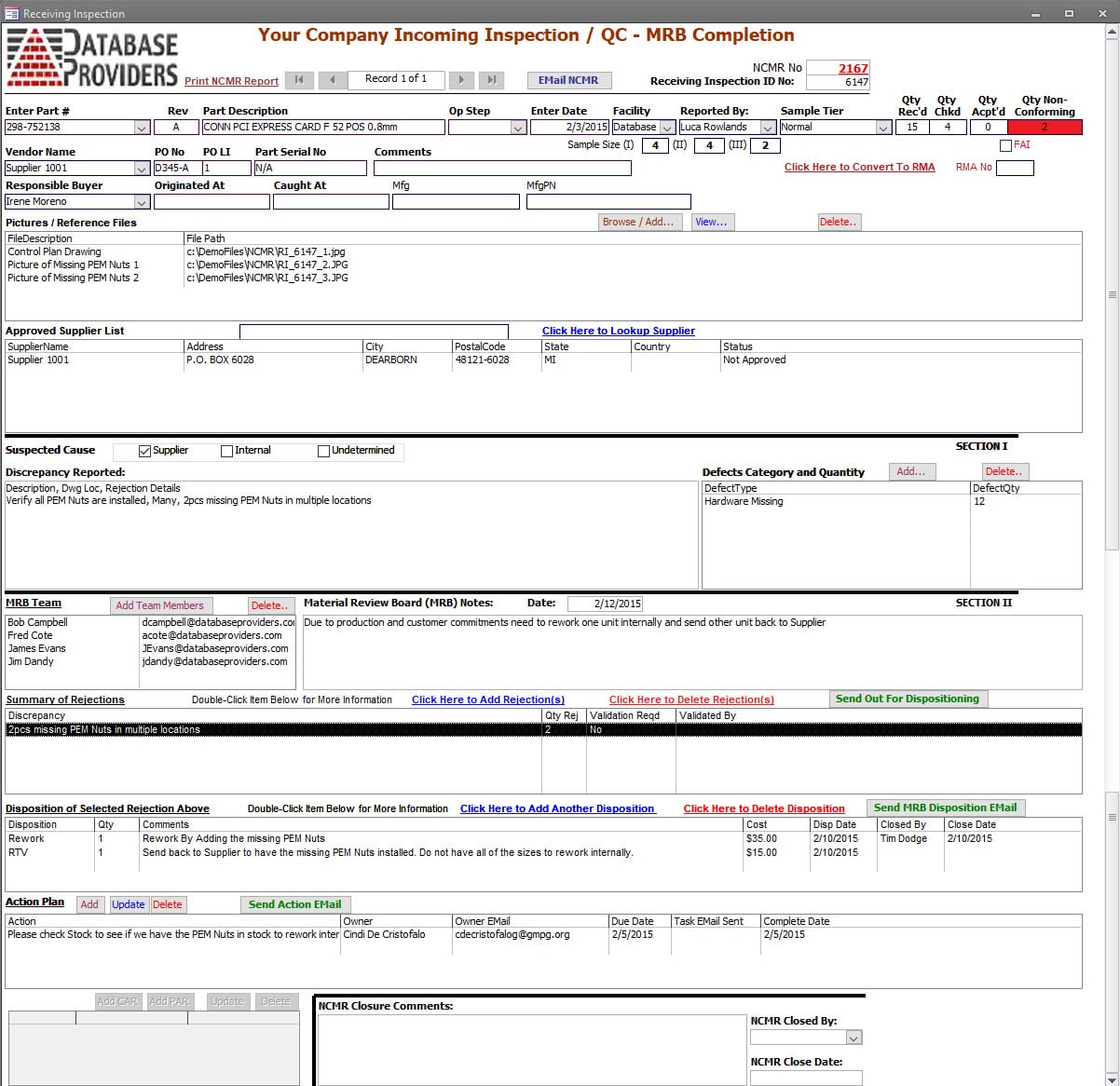

For NonConforming Material, the discrepancy is identified. and a unique identifier is created for the Inspection record.

Additional files can be linked to the inspection record for the non-conformance, such as red-lined drawings, and pictures of non-conformances.

When used, the Defect Category and Quantity can be captured for Pareto Chart reporting purposes.

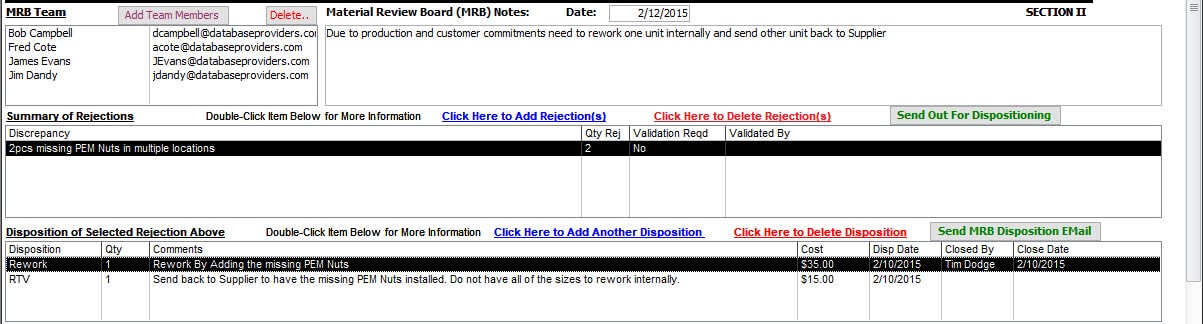

The MRB Team can be identified.

All rejections can be identified individually. Useful when more than one discrepancy is found within the inspected lot. Each rejection can have multiple dispositions and those dispositions are identified. (E.g. some quantity can be disposition to be reworked internally due to production demand, and the rest of quantity can be dispositioned to return to the vendor for repair or replacement.)

One-Click process to Generate and Send Email asking for dispositioning, and to those responsible for executing the disposition.

Actions (or task items) can be entered and assigned to specific parties (individual) throughout the process. Open Action items are visible in the dashboard.

NOTE: If the Corrective Action module is also purchased, then in the event a Corrective Action is warranted, one-click process creates a corrective action and links to the inspection record.

NonConformance Identification

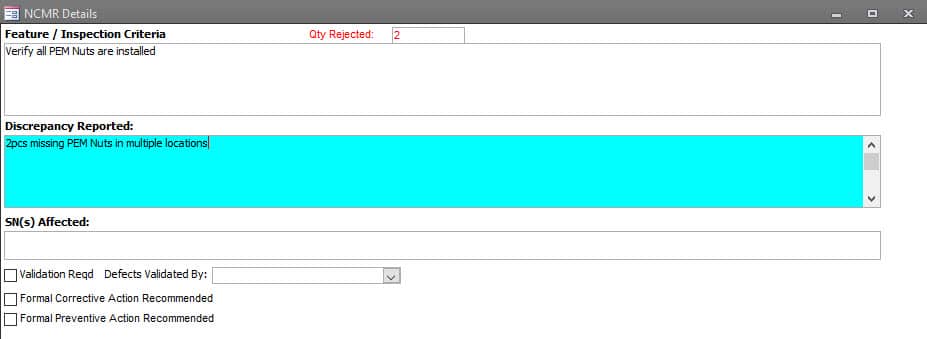

All Discrepancies found can be recorded in the inspection record.

Each Discrepancy contains the Expected Condition and the Discrepancy.

Serial Numbers and Lot Numbers can be added into Each Discrepancy recorded.

NonConformance Dispositioning

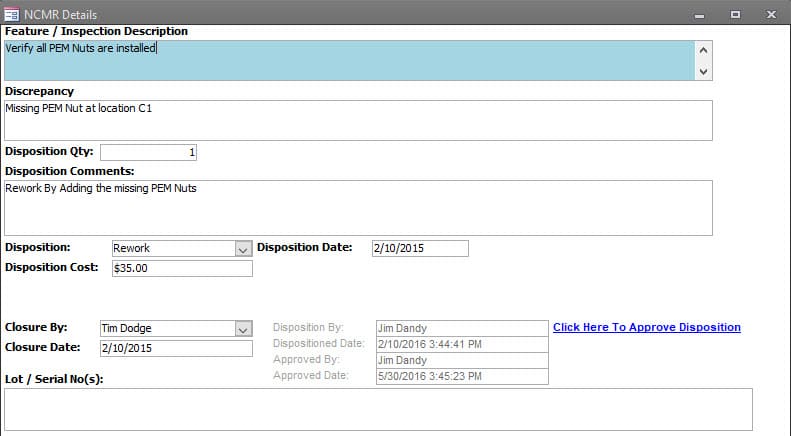

Each Discrepancy can have Multiple Dispositions.

Each Disposition entered shows the Expected Condition, the Discrepancy, the Disposition Quantity, the Disposition, Disposition Date.

The Disposition Cost is also available for for those organizations tracking Cost of Quality (CoQ).